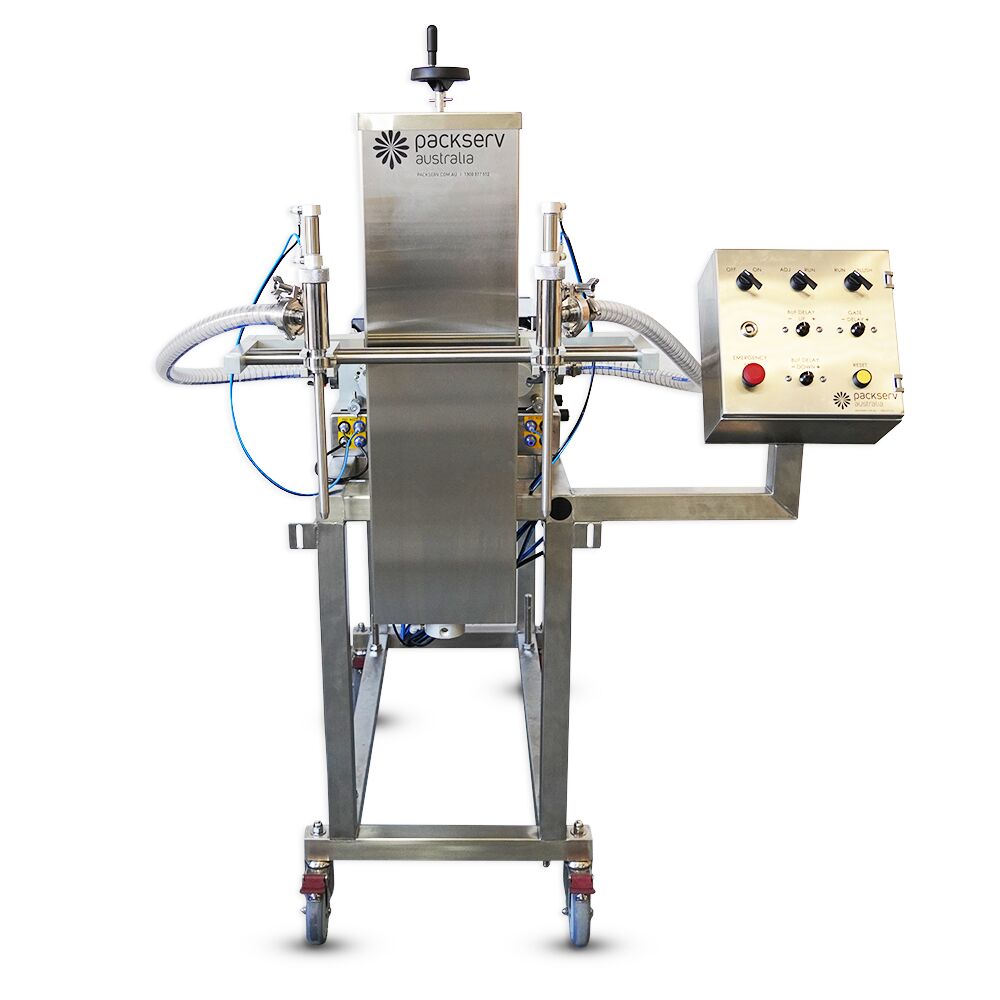

Our PFM-3-2C Auto Twin Head Filler is a fully automatic filing machine designed for liquids, pastes, creams and viscous products. Built for reliability and ease of use, this compact, heavy duty filler features an all pneumatic design that performs consistently in demanding production environments, while remaining easy to clean and maintain.

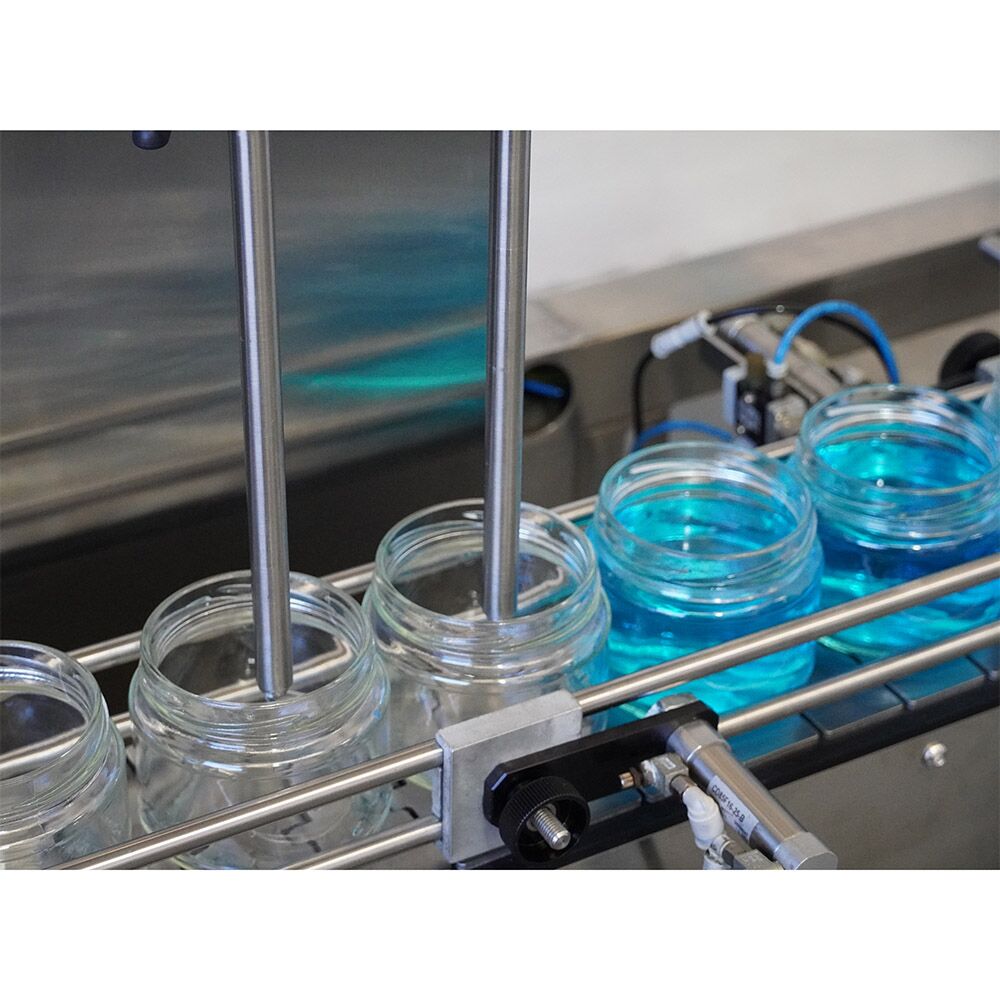

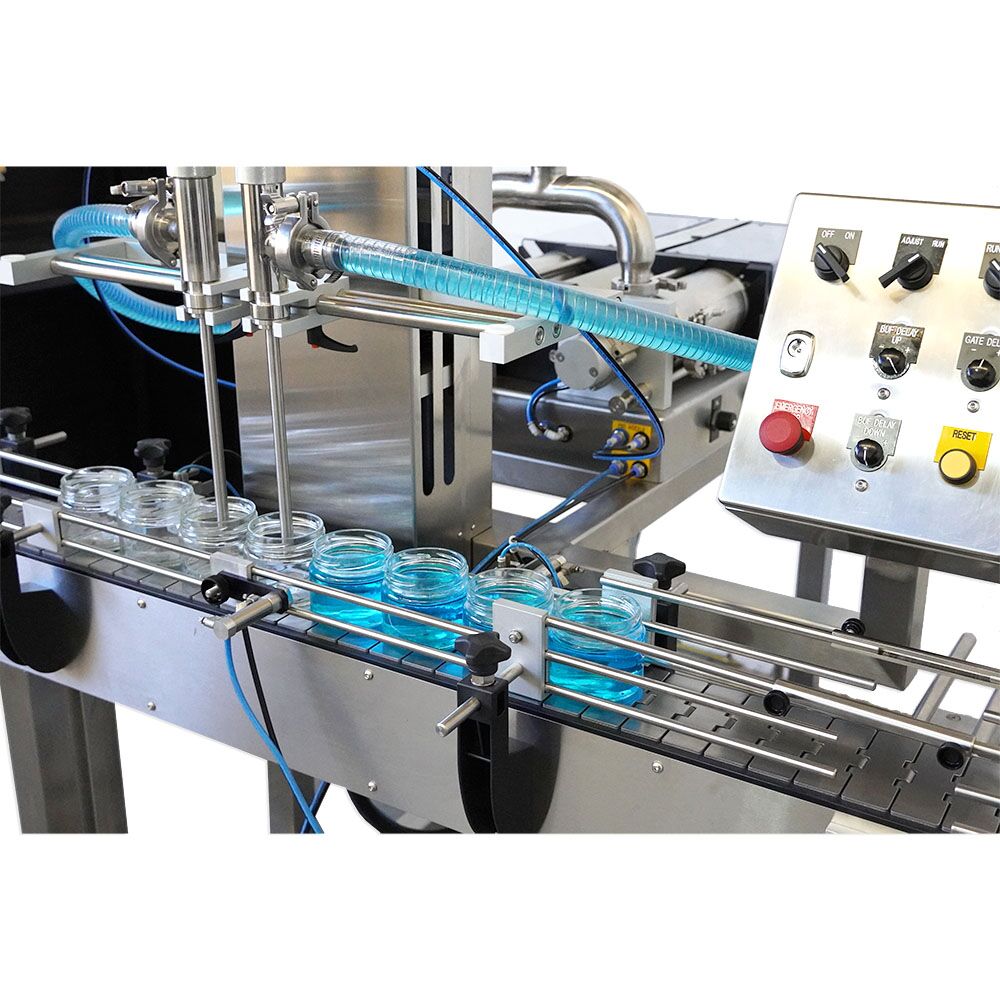

Engineered for seamless integrationinto a full-scale production line, the PFM-3-2C is trolley mounted with lockable castors and connects easily to a continuously running slat conveyor. It includes essential safety and accuracy features as standard, including a no bottle no fill safety mechanism and a container gating system to ensure precise, controlled filling.

Positive shut-off nozzles and a bottom up filling assembly allow the machine to handle a wide range of products, from thin liquids to thick pastes and creams. The valve system comfortably handles temperatures up to 65 C (149 F), with an optional high temperature valve available for hot fill applications above this range. The PFM-3-2C filling machine is also capable of filling products with suspended solids, eliminating the need for multiple machines or costly change parts.

The cylinder design of the automatic filling machine enables quicker dismantling and easier, more thorough cleaning of cylinder wet parts. A variety of product supply methods can be used depending on the nature of the product including twin port hoppers and custom inlet assemblies.

For operator safety, the stroke adjuster and air/product cylinder drive assembly are enclosed by an interlocked polycarbonate cover, automatically stopping the machine if opened during operation.

*Rent: Brand and model may vary. The machine will be identical in function.

Reviews

There are no reviews yet.